Job Safety Analysis (JSA) is a vital tool for any industry and getting the implementation process correct is key to your HSE success.

However, we also understand that no single Job Safety Analysis process meets every industry requirement. This is why we have landed where we are with the final design.

In fact, our final design has been built around requests from the likes of OSHA, DNV, ABS, US Coast Guard, UK HSE, Australian Mines Department and probably 80% of all major oil companies.

We all know JSAs play a vital part in risk mitigation, but poor implementation of this process has the potential to delay tasks, drive-up cost, or simply result in poor analysis due to operational time pressures.

Locstatt offers the incorporation of both digital mobile data integration and the option for paper-based tracking when required. Our JSA module is a perfect example of this process.

So, what is a Job Safety Analysis?

The amount of detail varies, however a summary of the JSA Creation Process is as follows:

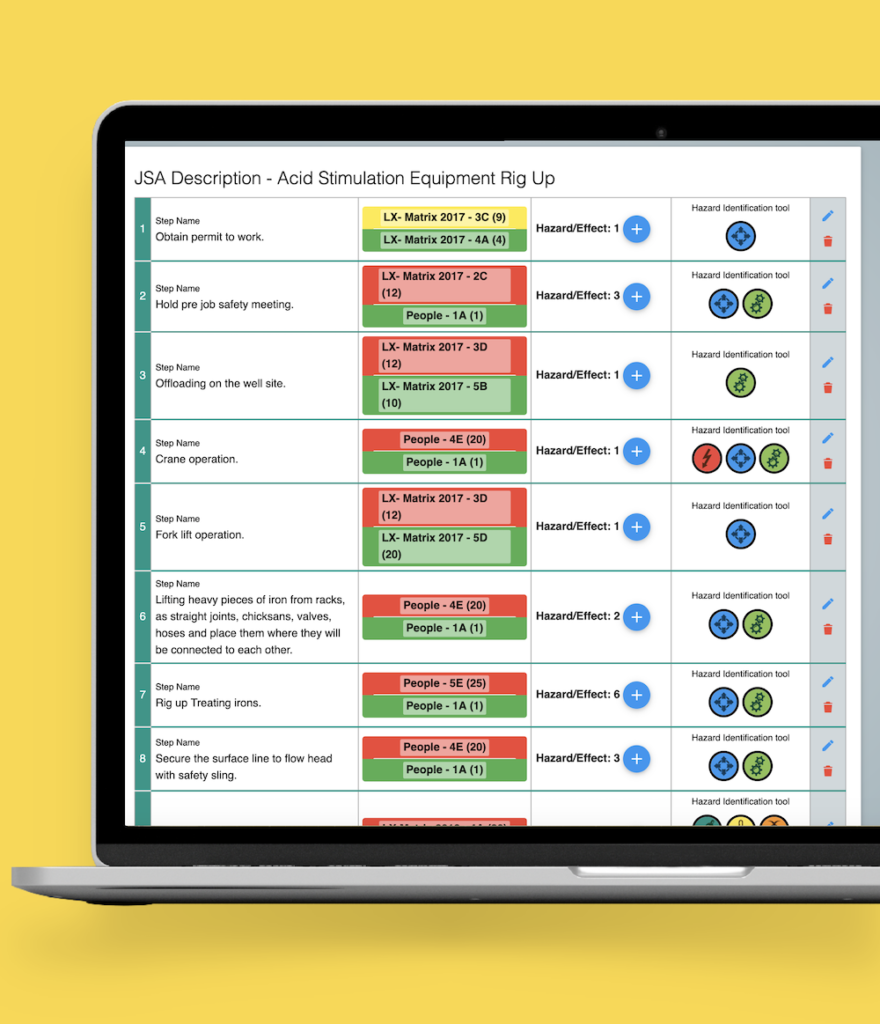

- Break down actions for the complete job into small tasks.

- Identify hazards associated with each of those tasks.

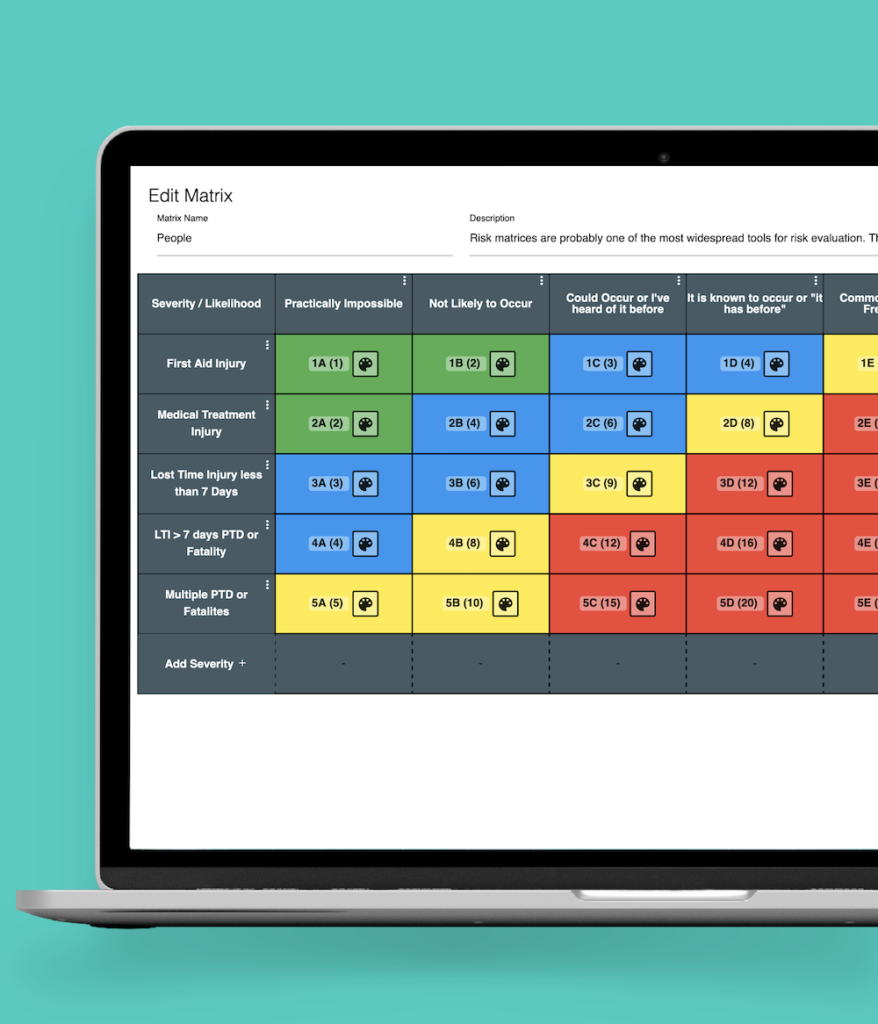

- Rank the hazards on a common risk matrix without mitigation controls.

- Design and agree on mitigation controls for identified hazards.

- Rank the hazards on the same risk matrix to demonstrate risk has been reduced to an acceptable level.

JSA LIBRARY

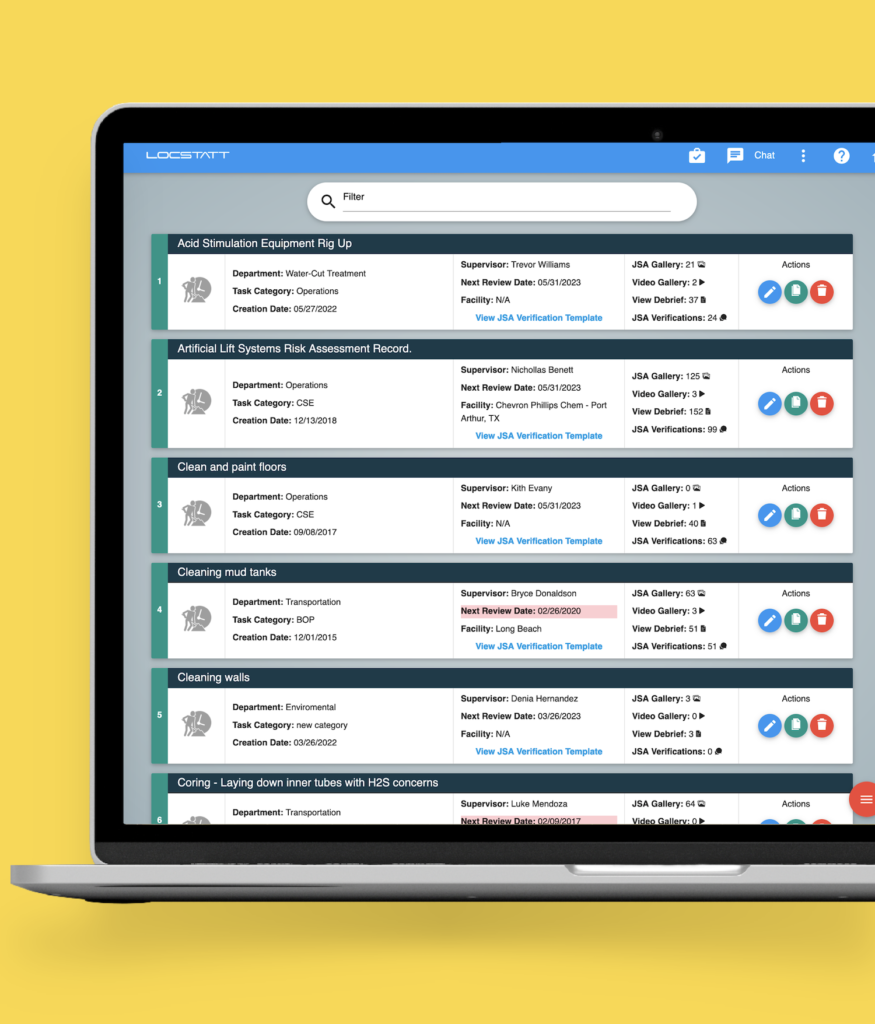

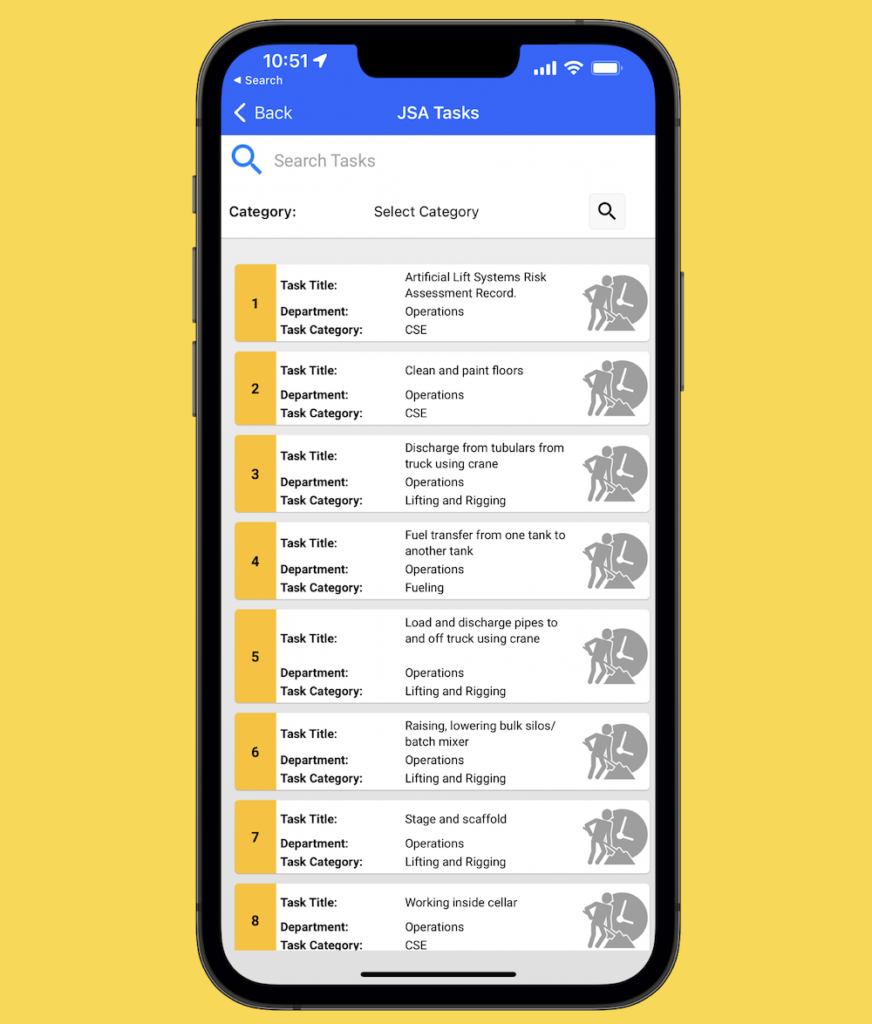

The Locstatt JSA Library tool offers a Comprehensive Database of Lessons Learned that Apply to You and Your Industry!

Don’t start with a completely blank page. Offer a formal library including pictures and video that highlight a step-by-step process including a history of when things went wrong. This process will clearly communicate to your crew the perils to be avoided.

The ability to swap between mobile technology and paper & pen (via Word docs or Excel) is a key component for your JSA Creation Process and allows for the best of both worlds.

Distinctive Characteristics include:

1. Electronic JSA Library

Choose and print from a comprehensive JSA Library as opposed to a blank sheet of paper.

2. Debrief & Comments History

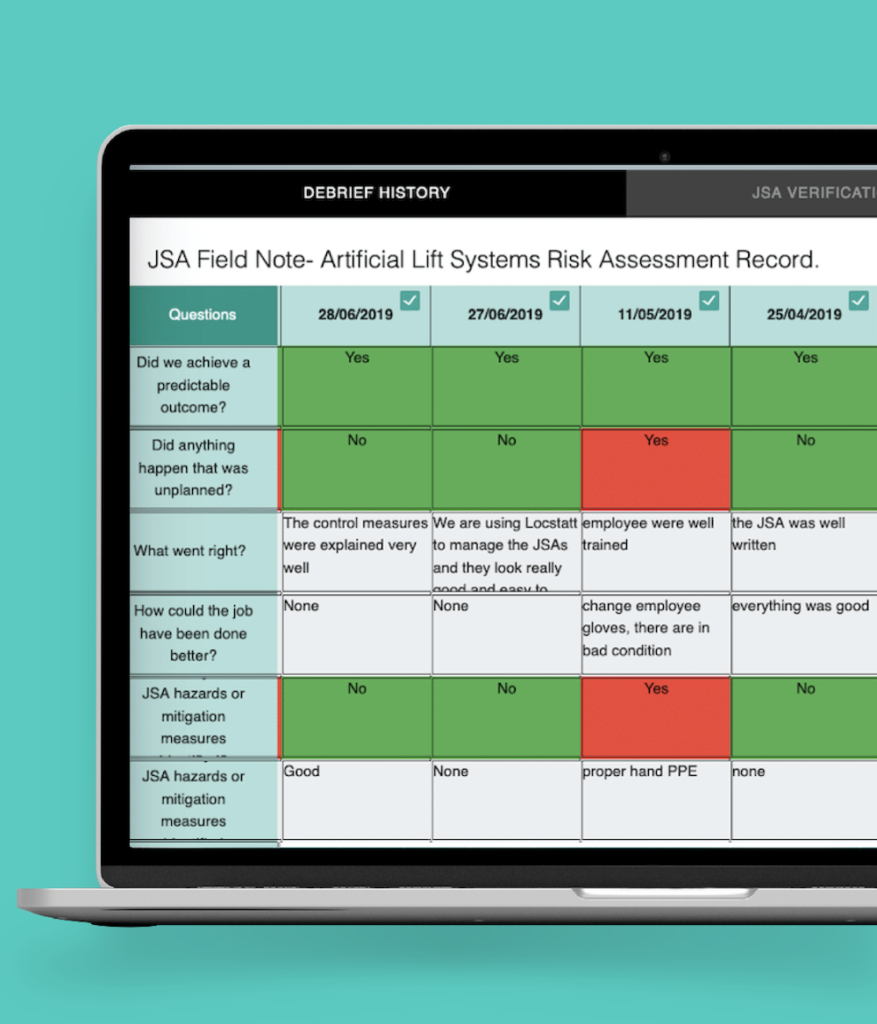

Allow site supervisors access to the wealth of knowledge accumulated over years of practical experience from known hazards on specific operations.

3. Customizable Risk Matrices

Specify a complete set of Risk Matrices needed for specific jobs.

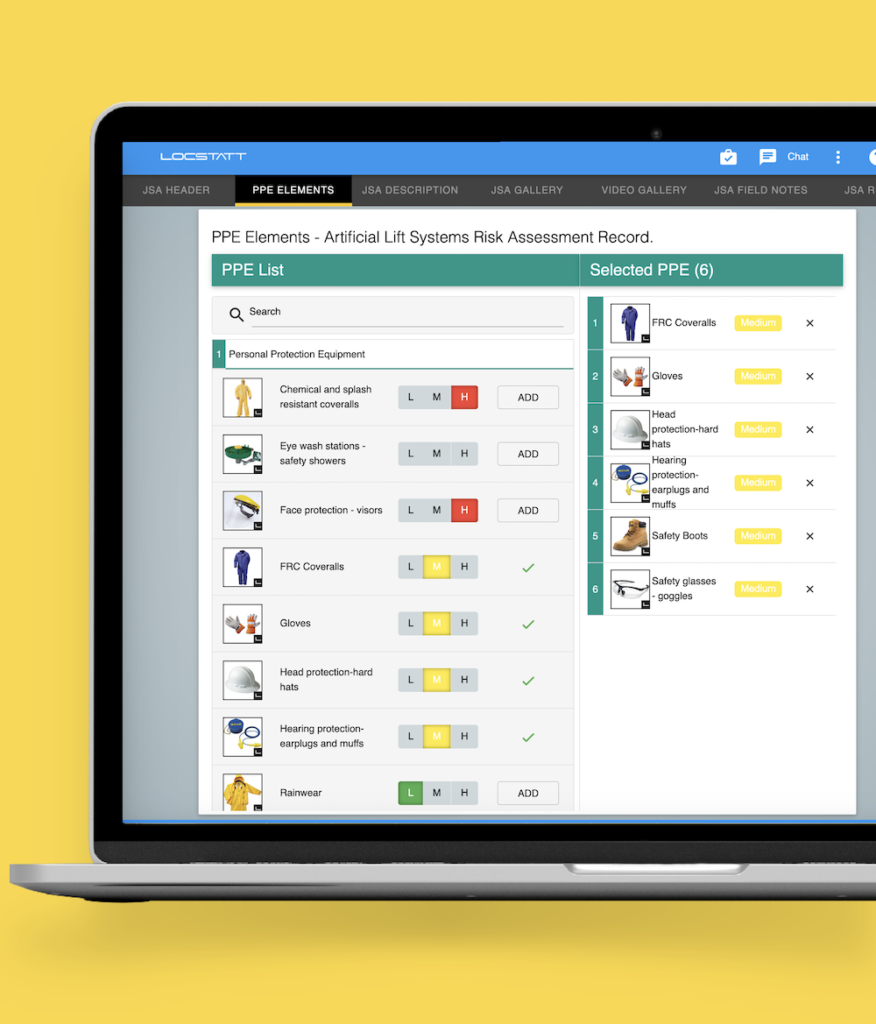

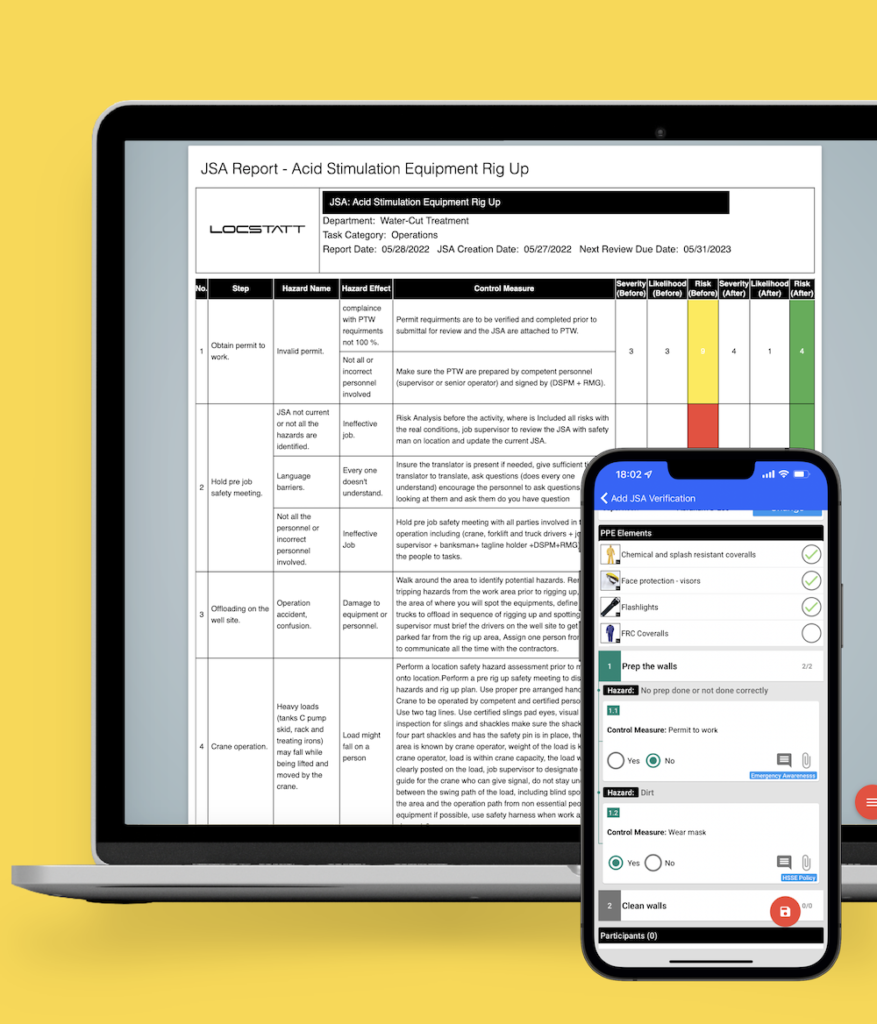

4. PPE Elements Library

Create an entire JSA library from a complete list of Groups and PPE elements.

5. Control Measures & Hazard Identifications

Create and customize your own Company library of JSAs with categorized departments, job titles and task categories. Then create each JSA with Hazards, Hazard Effects, Control measures, HSE Elements, Risks and Hazard Identifications Tools. Finally, make this entire Library available in the Mobile application to Create JSA Verifications and JSA Meetings.

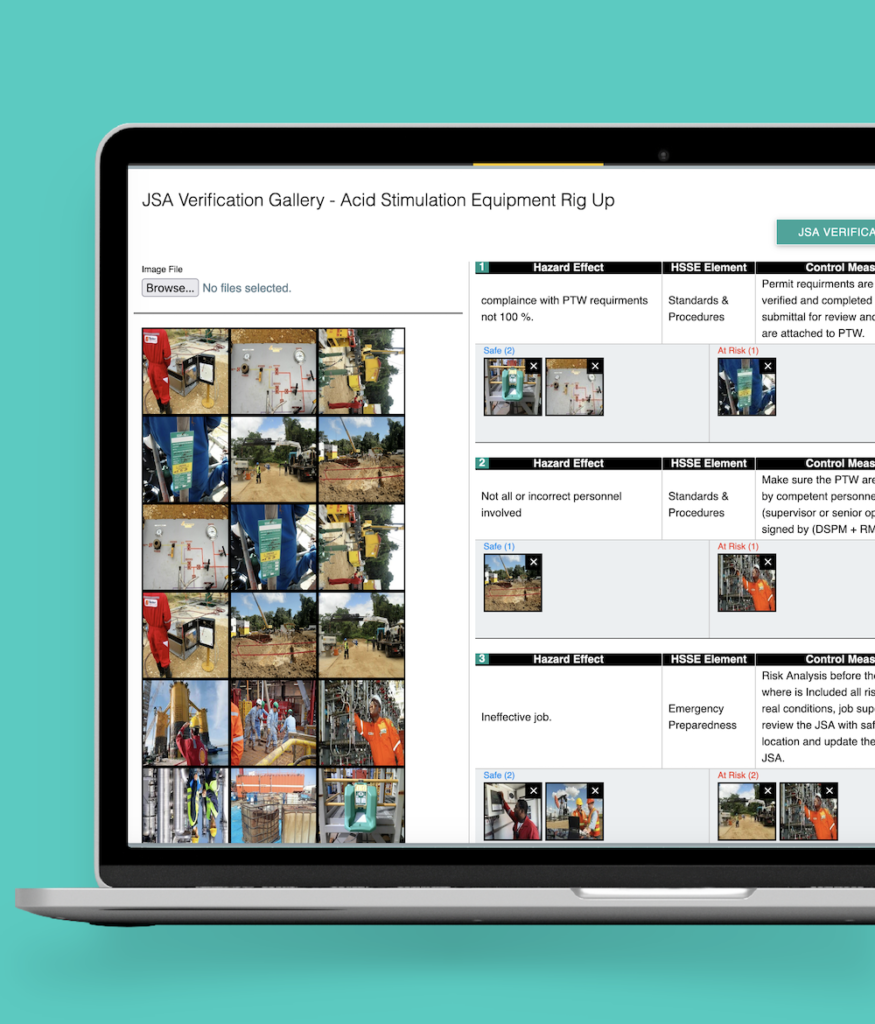

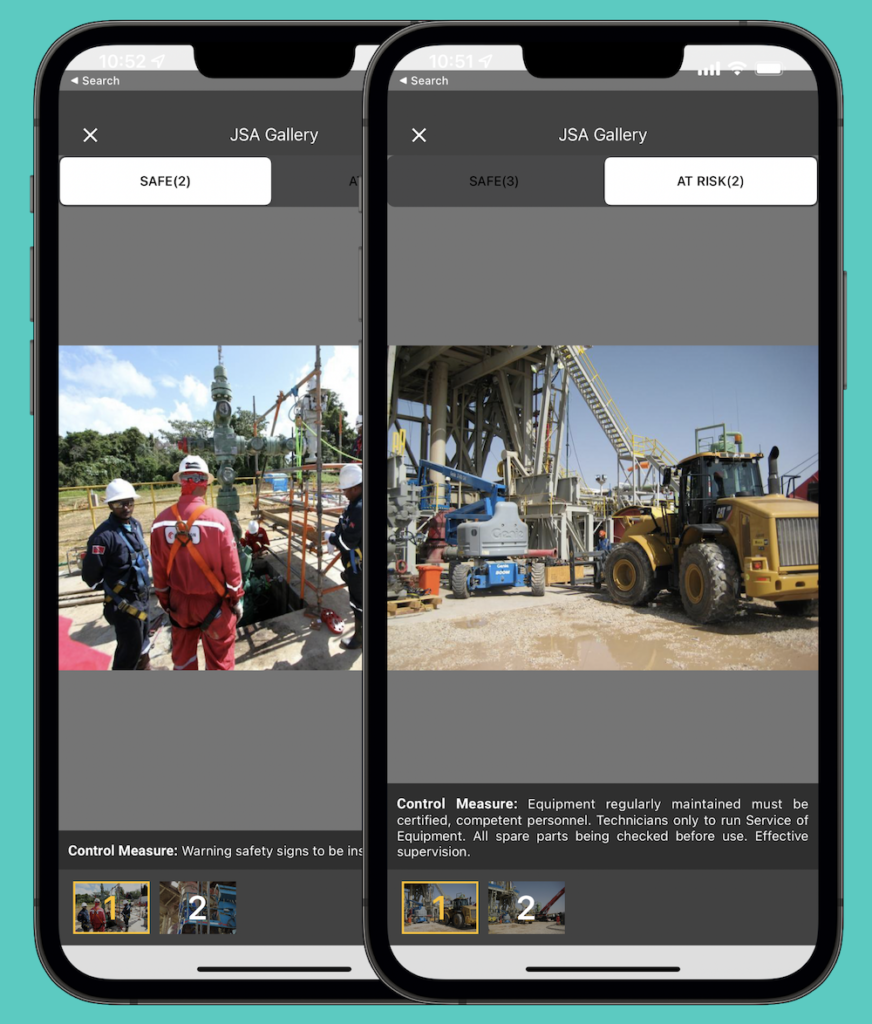

6. JSA Photo & Video Library

Draw from a Gallery of photos for each JSA, then attach these photos to show Safe and At-Risk actions for each Control Measure. This JSA feature on the Workstation Mobile App makes the task of discussing step-by-step safety topics clear & simple in any Meeting. Plus, the linked videos help to explain or emphasize a specific job at hand.

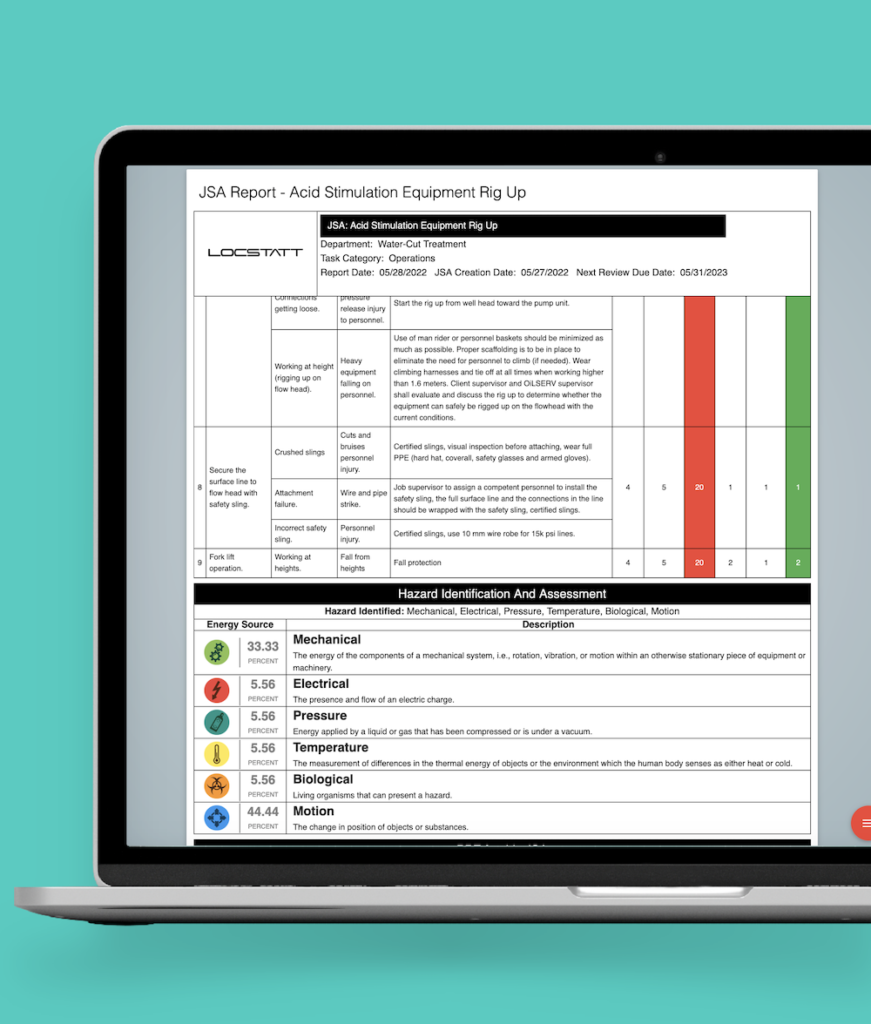

7. JSA Report – PDF Version

Review each JSA using the Locstatt web system and export to PDF for email or printing when required.

8. Shared JSAs

Contractors can share their own JSAs with Owners. This allows a smooth transition for contractor personnel to perform JSA Verifications and JSA Meetings at the Owner’s facility.

How is the JSA Meeting or Implementation Process delivered?

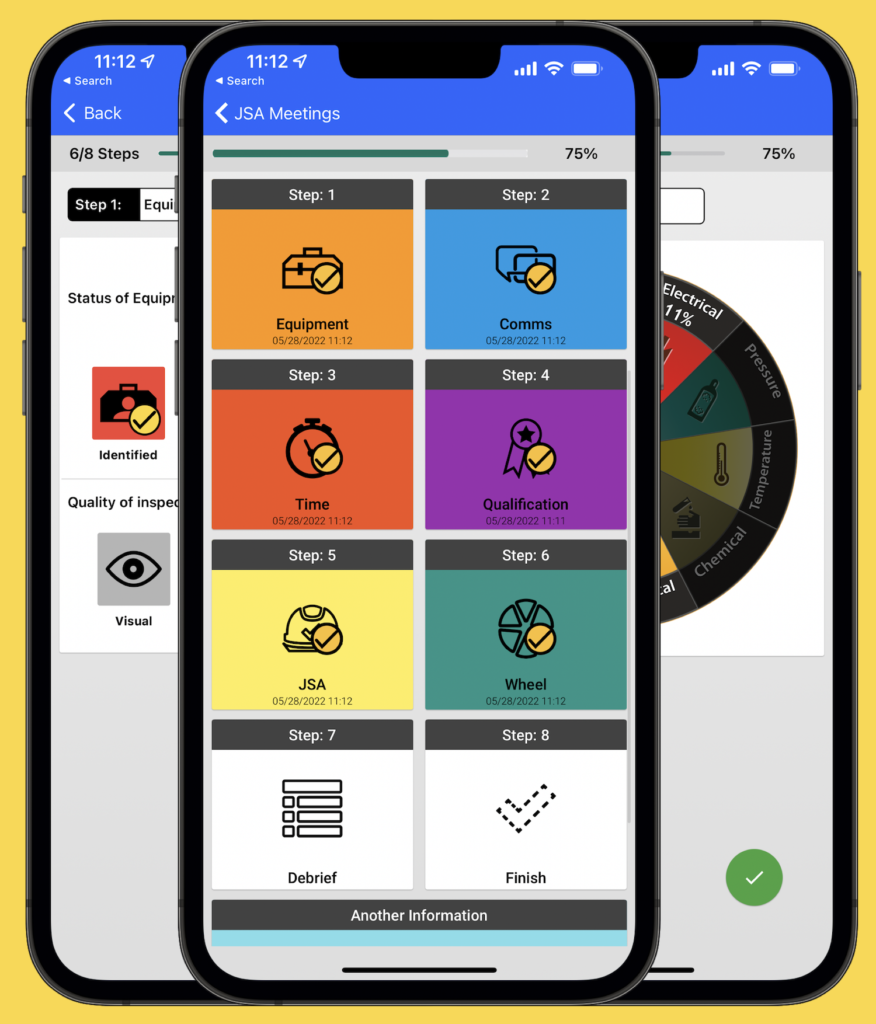

The Locstatt JSA module follows a predictable path for JSA Meetings. It is designed to guide your supervisor step-by-step, while also detailing the JSA expectations. On job completion, the JSA verifications are then compressed for accurate analysis.

Distinctive Characteristics include:

1. JSAs – Online and Offline Mode

Supervisors work with the Workstation app and download the JSAs ready for use – Online or Offline.

2. JSA Galleries

Download the JSA gallery to provide photos within the control measures to support discussion of Task related topics.

The entire Locstatt JSA library, including Photos of Safe or At-Risk actions with step-by-step presentations, was produced during the creation of prior completed JSAs. Hence, at every opportunity, supervisors will look for multiple opportunities to share this enormous wealth of retained knowledge.

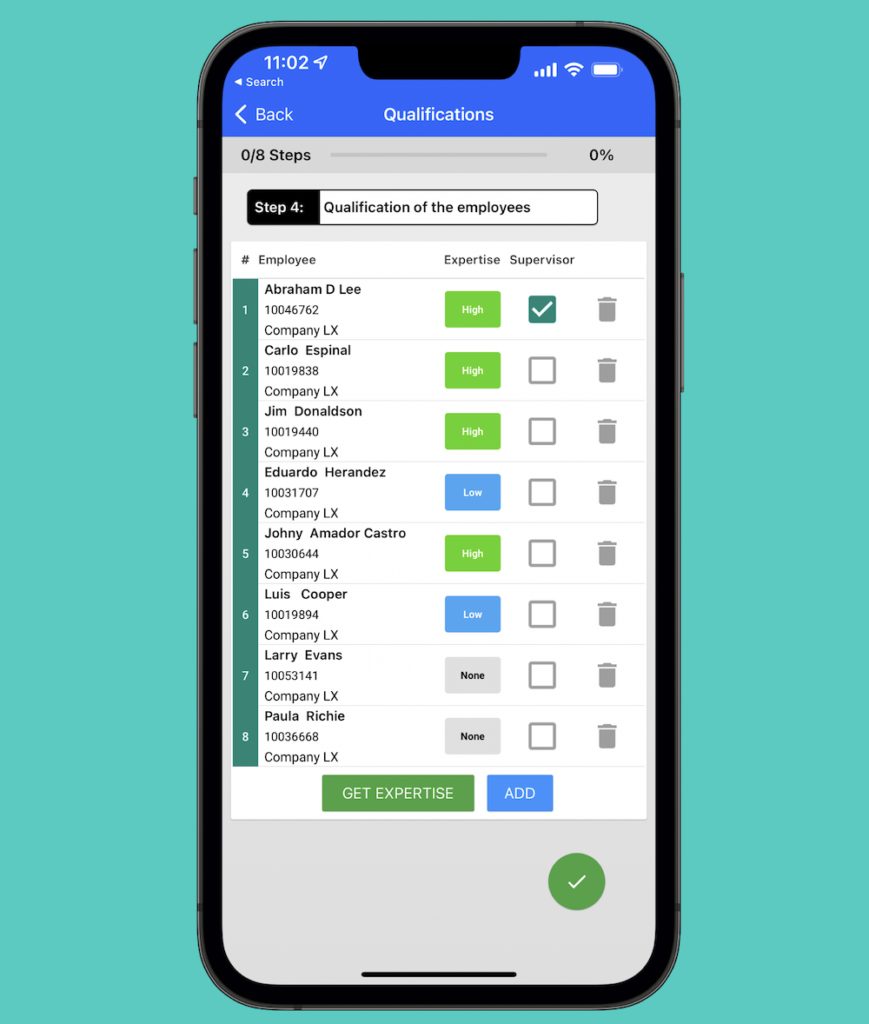

3. JSA Expertise

JSA Meetings are created using any JSA from your Company Library. Supervisors can also see in real time how many times each crew member has performed the specific associated task.

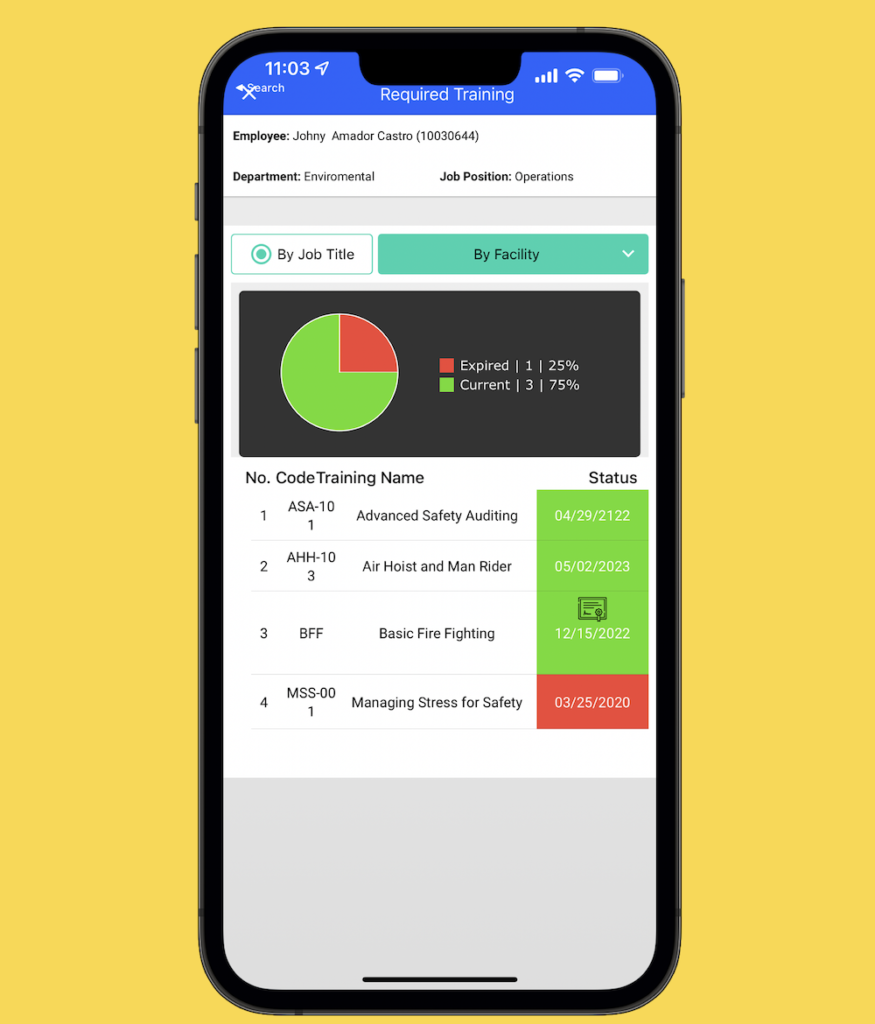

4. Required Training Status -Job Positions

At the same time you can choose any participant of the meeting and see in real time individual crew training records corresponding to their job position.

5. JSA Meeting Steps

Company Customized Options can be listed for Supervisors to assist as memory joggers with options such as Equipment checks, Time checks, Qualification or Training checks, Hazard wheel etc.

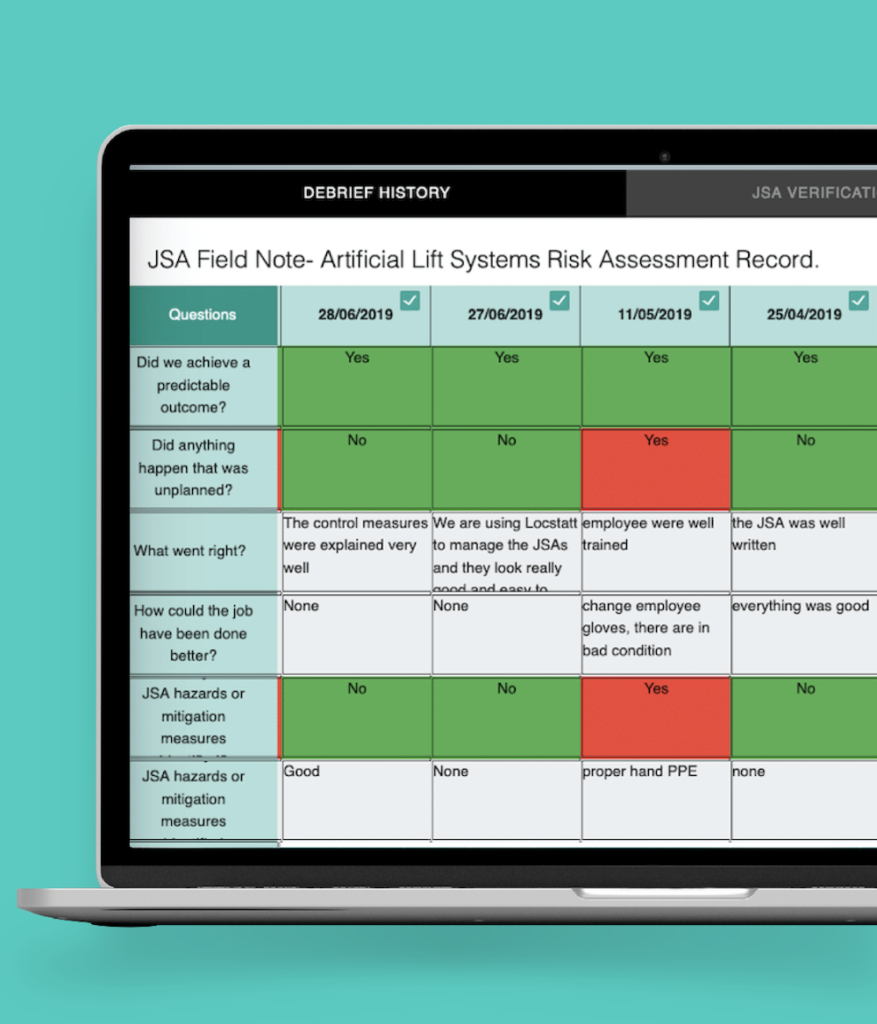

6. JSA Task Debrief

What went right or what went wrong during execution of the task? This information is available for subsequent supervisors performing the job. They can view all debriefs and JSA verification comments gained from in-house knowledge while other supervisors were performing the same task.

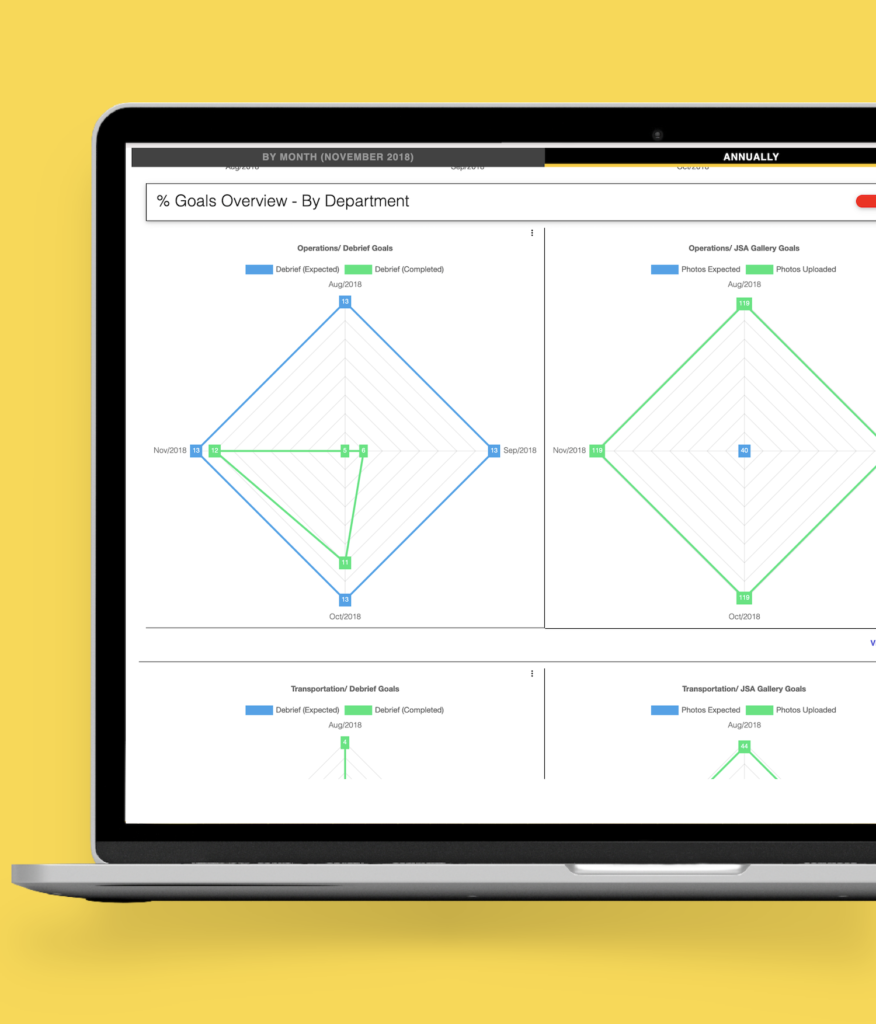

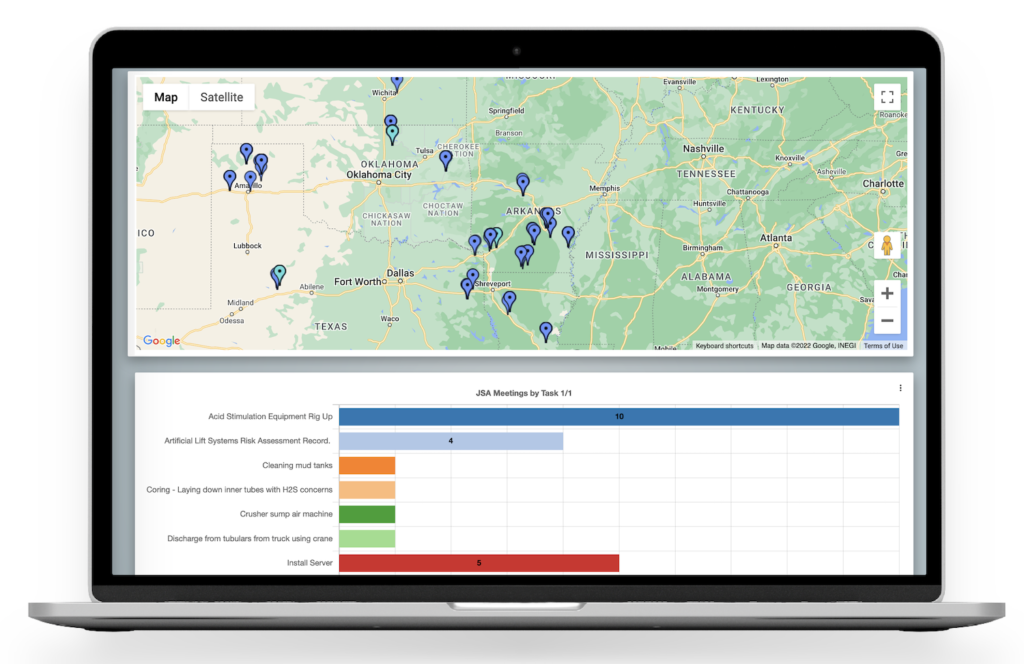

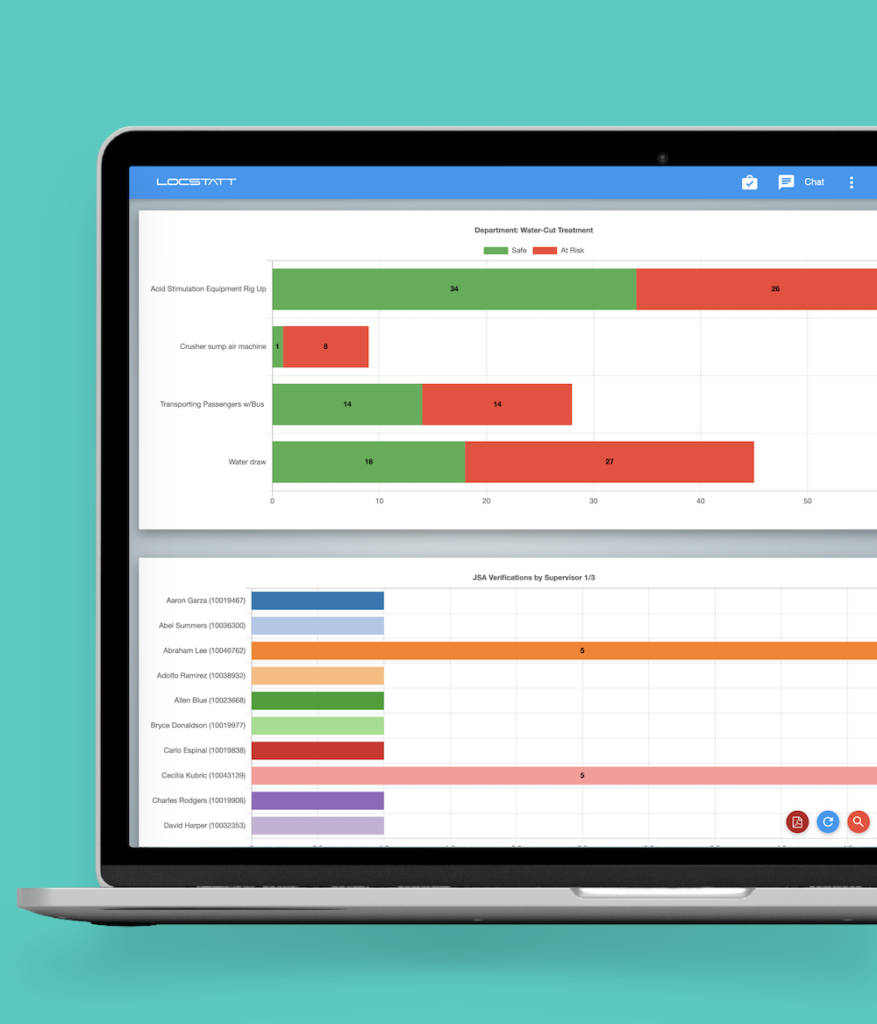

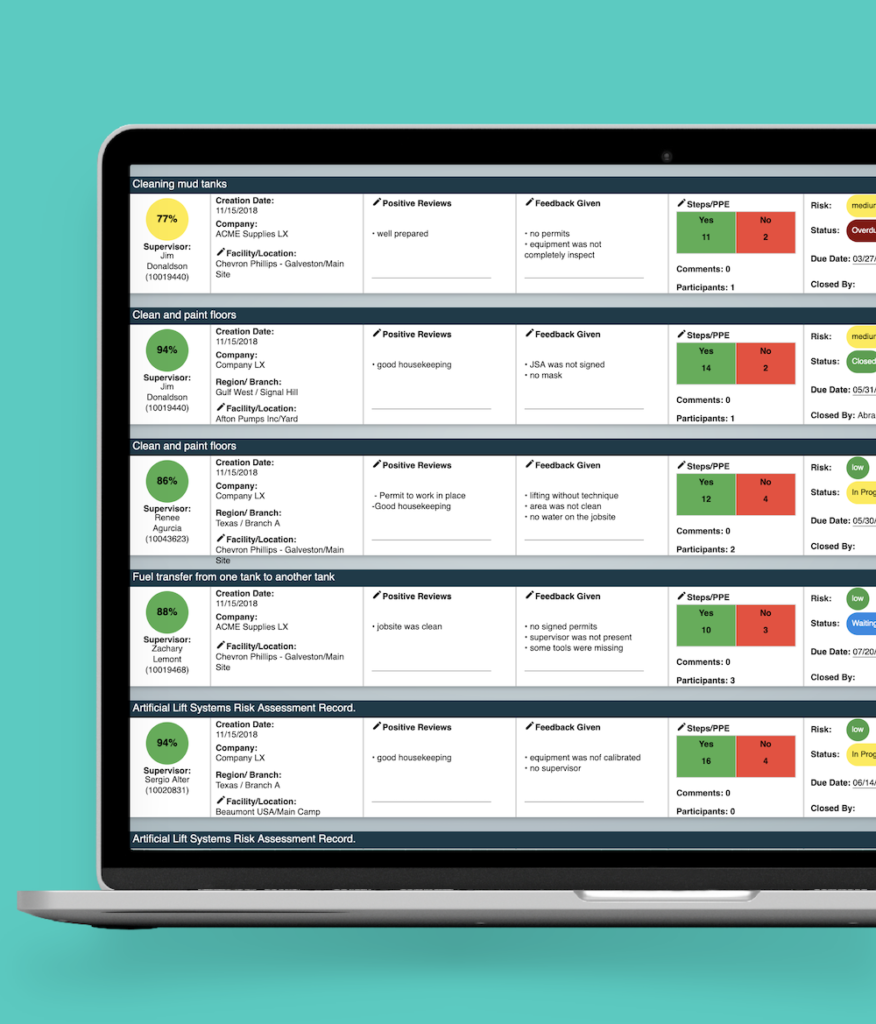

The JSA Meetings Component offers a complete overview of charts and reports showing a detailed monthly analysis. Company Meetings can be viewed by Facility, JSA Tasks, Departments, or HSE Elements, etc.

Job safety Analysis – JSA Verification Process

The JSA Verification Process is a very powerful tool

Five minutes spent completing a JSA Verification can lead to a further 15 or 20 physically verified mitigation measures. Once this data is compressed and analyzed, it is very easy to see which mitigation measures are consistently used, and which are not. This in turn gives supervisors clear direction & understanding for what needs to be done, and where they need to focus their JSA discussions.

Distinctive Characteristics include:

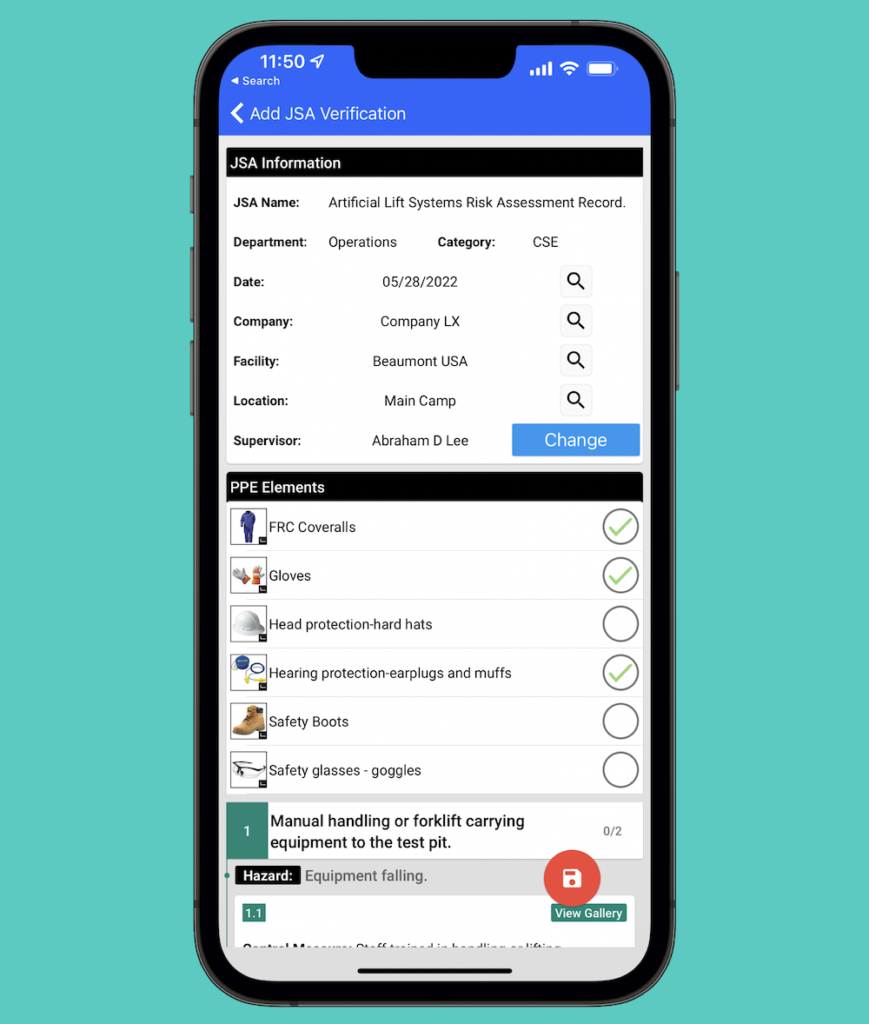

1. JSA Verification Form

Firstly, select the Company/ Facility/ Location and the Task to be performed. Then simply assess if the employees are wearing the correct PPE for the selected JSA.

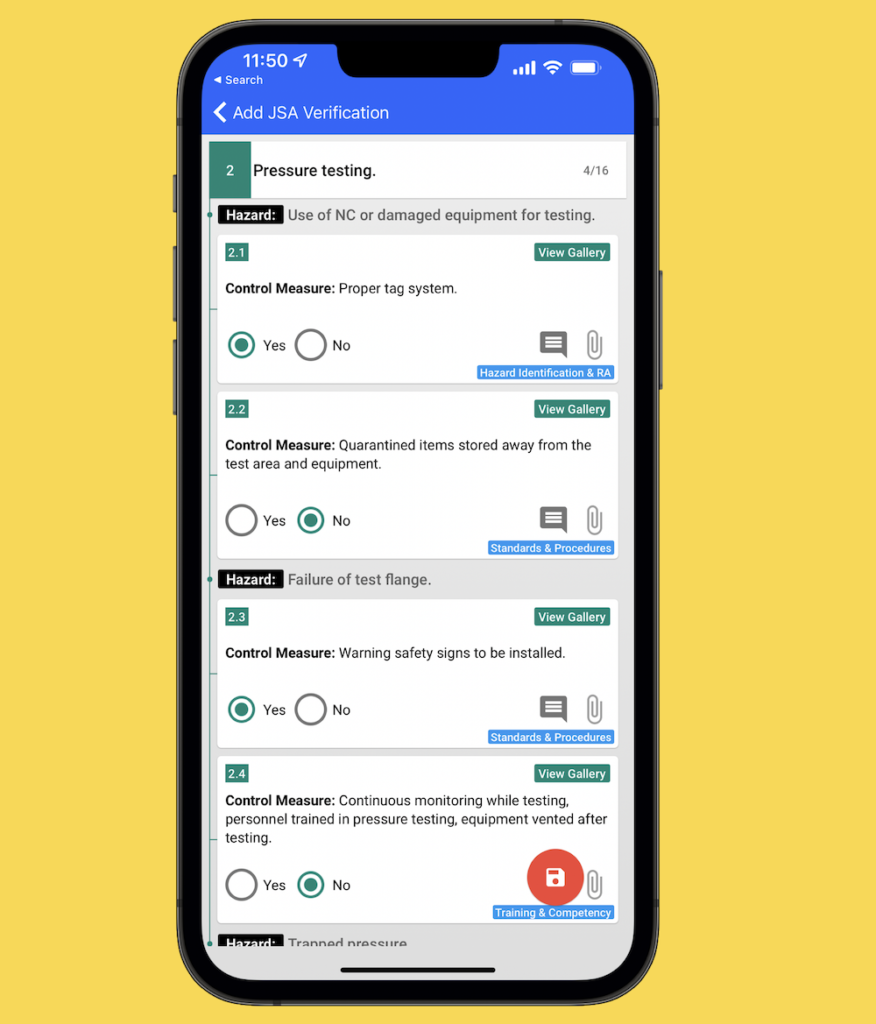

2. Verify the Correct Procedure

Secondly, determine if each control measure being used is following the correct procedure. Take photos, add comments, plus make a note of all employees involved in the JSA Verification.

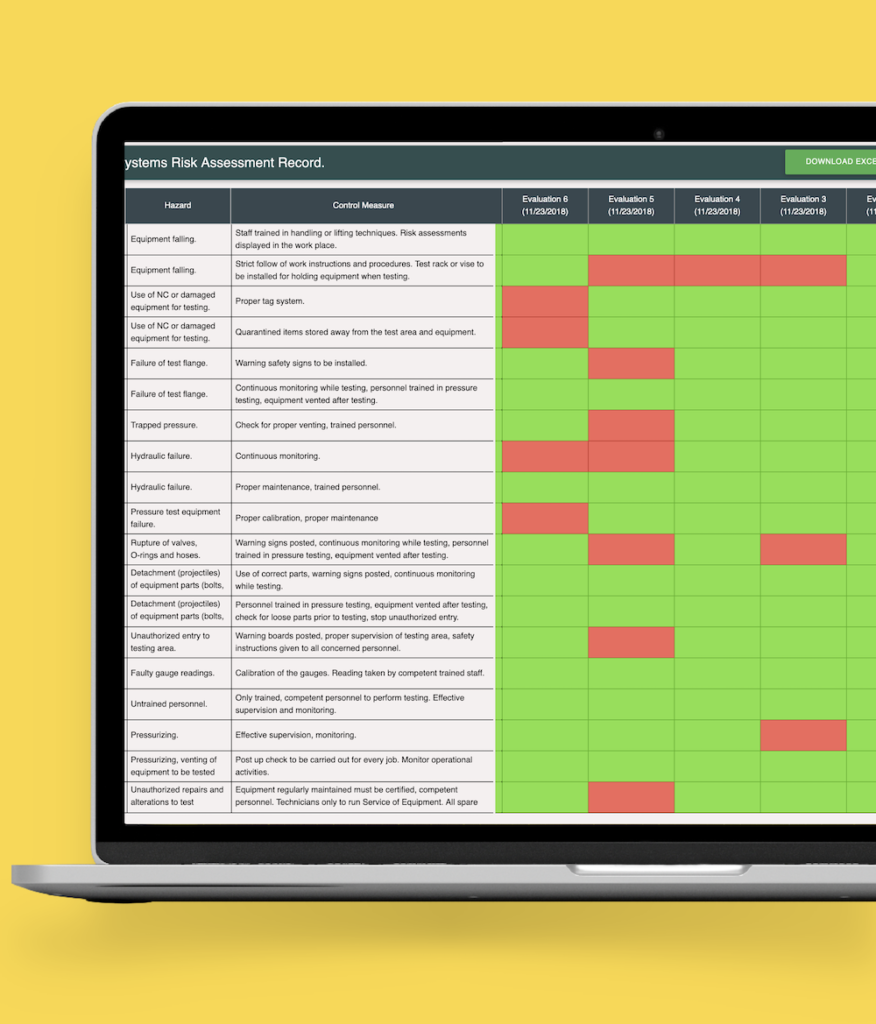

3. Verification Matrix

The Company Performance Overview report offers a Verification Matrix that shows a complete overview of all control measures and hazards.

4. JSA Verification Reports

The Web Application delivers multiple Reports showing a comprehensive analysis of Compressed Data by Department, Company, Client, JSA task, Facilities and Locations, etc.

5. Remedial Action Plan

Supervisors can review and track all verifications to pinpoint major issues associated with each job, task, department, facility, or Region, etc

The Locstatt JSA system is a powerful tool to support your SMS, so schedule a demo today.